Whether you work in the packaging industry, sign-making industry, or any other industry that requires precise cutting and shaping, understanding the features and capabilities of flatbed blades is crucial. Flatbed blades are:

- Essential components in the printing and manufacturing world.

- Playing a pivotal role in cutting.

- Finishing a wide variety of materials.

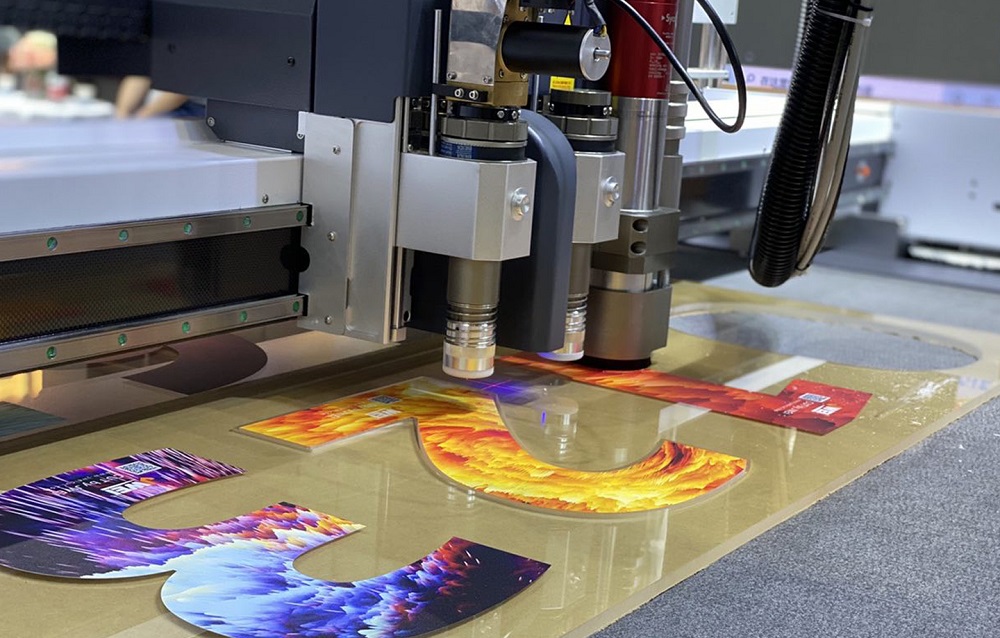

These blades are designed for use in flatbed cutting machines, which are renowned for their precision, versatility, and efficiency.

Let us explore five essential facets of flatbed blades, providing insights to assist you in optimising their use in your operations.

Types And Compositions

There are several varieties of flatbed blades, each designed for certain materials and uses. Choosing the correct sort of blade is essential for getting the best results. Standard steel blades are good for paper and cardboard, while more robust carbide and titanium blades are made for harder materials like plastic and metal. Understanding the differences between each type of blade and how to use it can ensure precise and efficient cutting, minimizing wear and strain on your equipment. Such information will also help you make an informed decision.

Accuracy And Precision

One of its most notable characteristics is the extraordinary precision with which flatbed blades can cut. This accuracy is essential for complicated patterns and elaborate designs. It helps maintain precise measurements and clean edges. Whether you are making elaborate signage, personalized packaging, or complicated prototypes, the quality of the finished product may be greatly impacted by the precision of flatbed blades.

Durability And Longevity

The durability impacts the longevity and performance of a flatbed blade. Superior blades composed of high-quality materials can tolerate heavy use, retaining long-term sharpness and accuracy. Durable blades last longer between replacements, so you can be sure that your machine will run continuously and produce reliable results.

Setup And Compatibility

Flatbed blades should be compatible to work well with your cutting machine. This covers the settings and capabilities of the machine along with its physical fit. Proper setup and calibration are crucial to maximize the efficacy of the blade, minimize material waste, and prevent damage to the machine and blade. Maintaining optimal functionality may also need periodic upkeep and modifications.

Security And Handling

Flatbed blades are sharp and possibly hazardous equipment, even though they are essential to manufacturing. Accidents and injuries can be avoided with the use of appropriate safety precautions and handling techniques. This includes donning safety gear, changing blades following manufacturer specifications, and making certain that all users have received sufficient training in emergency protocols and safe operation.

To Sum Up

Flatbed blades have been deemed indispensable tools in the cutting and finishing process. They offer precision, versatility, and efficiency. By gaining a thorough understanding of the various types of blades, their applications, and the importance of durability, compatibility, and safety, you can make informed decisions that enhance the quality of your work along with the productivity of your operations. Whether you are a seasoned professional or new to the field, these insights into flatbed blades can help you achieve superior results in your projects.